UNION TOOL CO.

UNION TOOL CO.

Union Tool is engaged in manufacturing and sales of industrial cutting tools. One of its product lines is cemented carbide drills for electronic circuit boards (hereinafter, PCB Drills). It was the first Japanese company to start manufacturing and sales of PCB Drills in Japan in 1963, and since then, it has established itself as a leading company backed by its excellent technical skills and superior product quality.

PCB Drill

Broadly speaking, we have three types of drills, namely,

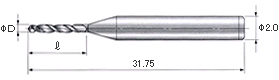

Ø2mm Shank drill K series

KMD (ultra-small diameter) series

| Model number | Features | Configuration | Size |

|---|---|---|---|

| KMD | Drill for high-speed rotationd rilling machine |

Straight type Undercut type |

φ0.075~φ0.25 |

| KMV | |||

| KMC | |||

| KUC | Undercut type | φ0.3~φ2.0 | |

| KCV | |||

| KID |

Reverse step drill for high-speed rotation drilling machine |

Straight type | φ2.05~φ4.05 |

Features

- Its specifications were specially developed for high-speed rotation drilling machine.

- Especially, with regard to small diameter (diameter is around 100 micron) drills, we use thoroughly tested drills.

- We have fine-tuned various performance parameters such as accuracy of hole position and wall roughness inside the hole such that we can meet the requirements of users.

- For achieving processing efficiency and required processing quality, we offer extensive test data as well as technical support.

- We have extensive line-up of peripheral devices and comprehensive support for preventing breakage issues such as dedicated 200 units package for increasing work efficiency, exclusive repolishing services for small diameter that exponentially reduces the processing cost, and spindle measurement device for maintaining product performance.

200 units case shown in the photograph is returnable case.

200 units case shown in the photograph is returnable case.

Normal size of Ø3.175mm shank diameter

MD (Ultra-small diameter) series

| Model number | Features | Configuration | Size |

|---|---|---|---|

| MD | Improved design for accuracy of hole position | Straight type | φ0.05~φ0.25 |

| MC | Design giving the top most emphasis to inner wall roughness | Undercut type | φ0.15~φ0.25 |

| MV | Design giving the top most emphasis the accuracy of hole position | Straight type | φ0.105~φ0.25 |

| MCV | Improved design for accuracy of hole position and inner wall roughness | Undercut type | φ0.2~φ0.25 |

UC (Small diameter) series

| Model number | Features | Configuration | Size |

|---|---|---|---|

| UC | General purpose drill | Undercut type | φ0.3~φ0.55 |

| UV | Design giving the top most emphasis the accuracy of hole position | Undercut type | φ0.3~φ0.75 |

UC35 series

| Model number | Features | Configuration | Size |

|---|---|---|---|

| UC35 | Design giving the top most emphasis to inner wall roughness | Undercut type | φ0.8~φ1.6 |

UM35 series

| Model number | Features | Configuration | Size |

|---|---|---|---|

| UM35 | Drill for multilayers | Undercut type | φ0.8~φ1.6 |

UA series

| Model number | Features | Configuration | Size |

|---|---|---|---|

| UA | Emphasis on inner wall | Undercut type | φ0.8~φ1.6 |

UM30 series

| Model number | Features | Configuration | Size |

|---|---|---|---|

| UM30 | Drill for multilayer board | Undercut type | φ1.65~φ3.175 |

ST series

| Model number | Features | Configuration | Size |

|---|---|---|---|

| ST | Drill for general purpose use | Straight type | φ0.6~φ3.175 |

ID30C series

| Model number | Features | Configuration | Size |

|---|---|---|---|

| ID30C | Reverse step drill for chip breaker and thinning | Straight type | φ3.2~φ6.5 |

SX24 series

| Model number | Features | Configuration | Size |

|---|---|---|---|

| SX24 | For long hole processing | Undercut type | φ0.5~φ1.6 |

※Please note that depending on the size, it will be custom production by order.

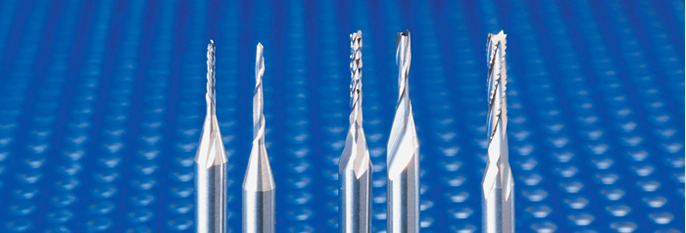

Router bits

We have an extensive line up of various route bits (about 16 types) from routing bits for general routing to routing metal for non-ferrous metals.

RCM/RHM series (Standard diamond-cut type router)

| Model number | Features | Configuration | Size |

|---|---|---|---|

| RCM | For general routing | Up draft | φ0.6~φ3.175 |

| RHM | Improved burr reduction design | Down draft | φ0.8~φ3.175 |

SC series (Spiral blade router with chip breaker)

| Model number | Features | Configuration | Size |

|---|---|---|---|

| SC | Improved burr reduction design | Up draft | φ0.6~φ3.175 |

SCM-FT series (Spiral blade router with chip breaker)

| Model number | Features | Configuration | Size |

|---|---|---|---|

| SCMB/SCM | For general routing | Up draft | φ0.8~φ1.8 |

RLE series (Spiral blade router with chip breaker)

| Model number | Features | Configuration | Size |

|---|---|---|---|

| RLE | For general routing | Up draft | φ1.0~φ2.0 |

RS series (Down draft 2-flute slitting router)

| Model number | Features | Configuration | Size |

|---|---|---|---|

| RS | Down draft for slitting | Down draft 2-flute | φ0.4~φ3.175 |

RP series (Up draft 2-flute slitting router)

| Model number | Features | Configuration | Size |

|---|---|---|---|

| RP | Up draft for slitting | Up draft 2-flute | φ0.4~φ3.175 |

RPU series (Up draft 2-flute slitting router with ULF coat)

| Model number | Features | Configuration | Size |

|---|---|---|---|

| RPU | Up draft for slitting | Up draft 2-flute | φ0.4~φ3.175 |

RAU series (For non-ferrous metal with ULF coat)

| Model number | Features | Configuration | Size |

|---|---|---|---|

| RAU | For non-ferrous metal board processing | End mill type | φ0.8~φ3.0 |

SF series (DP type 1-flute router)

| Model number | Features | Configuration | Size |

|---|---|---|---|

| SF | For soft material bases | Up draft 1-flute | φ0.8~φ3.175 |

SM series (Semi-lunar type cutter)

| Model number | Features | Configuration | Size |

|---|---|---|---|

| SM | For spot facing work | Straight 1-flute type | φ1.0~φ3.0 |

SI series (Straight 2-flute type)

| Model number | Features | Configuration | Size |

|---|---|---|---|

| SI | For long-life spot facing work | Straight 2-flute | φ1.0~φ3.0 |

IC series (Taper 2-flute)

| Model number | Features | Configuration | Size |

|---|---|---|---|

| IC | For taper spot facing work | 2-flute with taper | φ1.0~φ3.0 |

RV series (V-groove cutter)

| Model number | Features | Configuration | Size |

|---|---|---|---|

| RV | For V-groove work | V-groove cutter | φ1.0~φ3.175 |

RA series (For non-ferrous metal work)

| Model number | Features | Configuration | Size |

|---|---|---|---|

| RA | For non-ferrous metal board processing | End mill type | φ0.8~φ3.0 |

RI series (Notched straight 3-flute type)

| Model number | Features | Configuration | Size |

|---|---|---|---|

| RI | For contour finishing | For 3-flute | 0.8~3.175 |

※Please note that depending on the size, it will be custom production by order.

Peripheral devices

We offer peripheral devices for PCB tools. In recent years, quality requirements of cutting tools have become very rigorous.

Please help us in managing quality, precision, and life span.

Spindle Vibration Measurement Equipment OPTECH-RI-V plus

Optec RI-V plus has compact design and it is cordless. Union Tool’s indigenous technology allows high precision spindle vibration detection through simple settings.

Furthermore, function for measuring the number of rotations is also added, and number of rotations of spindle can also be measured. It is an indispensable product in the maintenance of machines.

Pressure & Vacuum Checker PV-CHECKER

PV-Checker is the measurement device for measuring or observing pressure, suction pressure, and bush contact of pressure foot. It is an indispensable device for managing the operating conditions of the drilling machine itself and managing the product quality for undertaking higher quality drilling work.

Contact Less Drill Diameter Measurement Equipment OPTECH-M/MA

Optec M is optical contactless external diameter measurement equipment for cemented carbide drill for printed-wiring boards. It solves the problems of drill voids through contactless measurement equipment. Moreover, optec MA can also measure blade diameter of routers and drills having even/odd number of blades. Furthermore, we can also offer special products with high resolution specifications.

In addition, we also have other peripheral devices for PCB such as ring setting machine and repolishing machine.

End Mills

Carbide End Mills

Union Tool's End Mills were developed from PCB drill manufacturing technology.

The appearance of End Mills resembles PCB drills, but they are able to form various shapes with tip and peripheral cutting edges, whereas drills bore holes only with tip edges.

Metal molds and mechanical parts are shaped with End Mills.